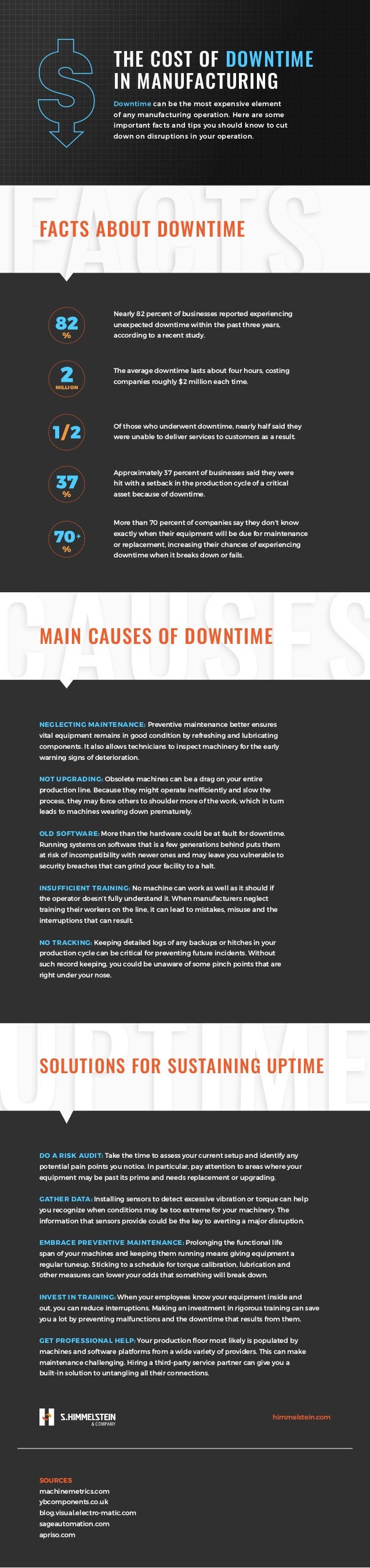

You’re probably well aware that in business, time is money. Our growing technological dependence means that one minor misconfiguration or full-scale system failure can lead to significantly reduced productivity — or worse still, complete business shutdown.

552 man-hours are lost as a result of problems with IT in Europe each year. This downtime reportedly results in a 37% drop in revenue generation, as the critical tools for business success are made unavailable.

Of course, the associated losses vary across sectors, as it is influenced by the number of staff affected, the impact on productivity, how long the downtime lasts for and the cost per employee per hour.

Taking manufacturing as an example, the average salary for a manufacturer is £29,419 (the equivalent of £15.32 per hour, based on a 40-hour week). Should downtime strike the factory floor, preventing 50 members of staff from doing 50% of their job for five hours, the business would face a loss of £1,915 for just one incident. As the scale of the downtime increases, so does the associated loss, causing a major impact on productivity and profitability.

In addition to this salary-based loss, businesses should also consider the loss in potential revenue that could be caused too. Clearly then, businesses need to put precautions in place to prevent downtime from happening.

Business Downtime: Causes & Prevention

What are the most common causes of business downtime? Studies have been carried out to establish this, although results can vary wildly. The overall causes of business downtime include hardware and software failure, human error, the weather and natural disasters, and power cuts.

Putting precautions in place is key to preventing these issues from arising. Here’s how you do it:

Keep Software Updated

Because software failure is such a prominent cause of business downtime, you should do all you can to keep yours up-to-date. Clicking ‘remind me later’ will no longer cut it. Make sure you install all available updates for your software to ensure it can continue performing optimally, minimising the risk of failure.

Mitigate the risk of outdated systems, which can include potential security flaws as technology advances and threats mount. Review your software at timely intervals to ensure it remains fit for purpose and relevant.

How much money you are losing when your site goes down? Check this Downtime Cost Calculator tool.

Train Employees

There is no way of completely eradicating human error, so invest in staff training to reduce the frequency of occurrences.

Ensure that all employees are fully aware how to use the technology and software they require for their role to prevent against issues like this from arising.

Hardware Replacements

All hardware falls victim to wear and tear eventually, more-so in specific sectors. For example, in manufacturing, machines and presses will require regular maintenance to ensure they remain functional and efficient.

Carrying out predictive and preventative maintenance can help this scenario, allowing you to address issues before they have the chance to arise.

Take these tips on board and prevent the impact business downtime can have.

Guide created by S. Himmelstein & Company a leading manufacturer of torque tranducers