Having a workshop can be a great investment. Maybe you’re a car dealer and you’re starting a workshop to allow for on-site repairs.

Perhaps you’re looking to open a workshop to start a building education business. Or maybe you’re just building one for your own personal use at home!

Whatever the purpose, you must understand that a workshop can be a pretty dangerous place.

There are several things you need in there to protect yourself and anyone else who will be there, be it customers, students, or employees.

Good tool storage

You need to create a solid system for tool storage and sorting. Make it as easy as possible to simply look at the storage and see if anything is missing.

Recording inventory is an essential safety measure that will appear a little later in this article.

A hanging tool cabinet is a perfect way of keeping all your tools safely stored. Of course, building one of those probably requires you to have your workshop ready!

A good way to get such a measure installed safely is a pegboard.

Inventory

You need to know what tools you have. You also need to know how many of those tools you have.

Some people feel a bit odd taking inventory. To some, it seems to signal a sense of distrust of the people you’re working with.

No one’s going to assume that you suspect them of stealing tools in order to harm others.

Inventory is simply a way of ensuring that you know where all the tools are. If you suddenly find one missing and no one knows where it is, then people will know to be careful when they move around.

Who knows where that sharp saw could be lying around?

Ducting

Workshops may produce repairs, cars, money, and injuries – many things are possible. But there’s one thing you’re definitely, 100% going to get in a workshop. That’s dust. Not just regular dust that we usually breathe in at home! I’m talking about think and dangerous dust, the kind that emits from sawing.

To protect yourself from this, you need a strong ventilation system known as ducting. Ducting can be an expensive and difficult process. There are ways to ease this pressure, though. Something like clamp-together ducts is perfect for people building their own workshops.

Lighting

Everyone needs to be able to see what they’re doing! Ensure you have strong lighting coming from the ceiling.

Make sure it’s not flickering; damaged bulbs must be replaced as soon as possible. I’d recommend getting some desktop lamps so that workers can adjust the amount of light they’re getting with ease.

First-aid measures

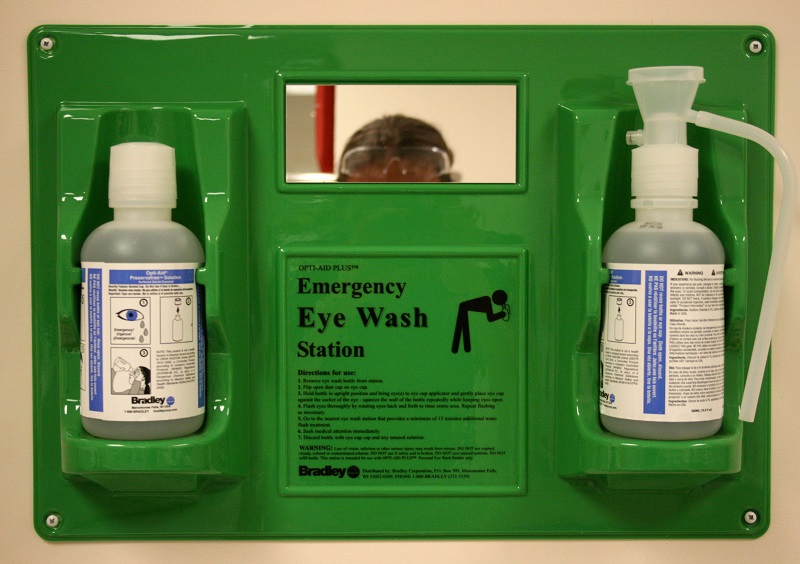

This is, probably, the most essential aspect. Injuries can happen. Prevention is extremely important, but we’re only human, right?

Ensure you have all the things someone could need to help themselves after common workplace injuries. An eyewash station is essential, in case someone forgot to wear their eye protection.

Bandages and antiseptic fluids are required for bleeding injuries.

You could also consider throwing some painkillers in there. But be careful! People shouldn’t be operating heavy machinery after using certain painkillers.

Protective Clothing

Protective clothing is essential in any workshop. Safety goggles, gloves, face masks, and boots are all important pieces of clothing to help protect you from potential hazards.

These should be worn at all times when working in the workshop, even if the operation being performed appears to pose no risk.

It’s also a good idea to have some spare sets of protective clothing in the workshop, just in case someone forgets theirs.

Emergency Protocols

Last but not least, you need an emergency protocol for your workshop. This should include procedures for dealing with fires, injuries, and power outages.

The procedures should be written down somewhere everyone can find them. Make sure to post a few copies around the workshop, so people won’t need to scramble for it in an emergency situation.

Ensure everyone knows the protocol and how to use the necessary equipment. Regular drills should be conducted to keep everyone up-to-date on the protocols and make sure they remember them when the time comes.

Safety Checks

It’s essential to regularly check the safety of the workshop. Check for anything that may pose a risk, such as loose wiring, exposed nails, and screws, or damaged tools.

Check that all the safety equipment is working and up-to-date. Make sure everyone is wearing the right protective clothing for the job they’re doing. Keep an eye out for any spills or trip hazards in the area and make sure that they are cleaned up as soon as possible.

Finally, make sure that everyone is following the safety protocols and using the proper equipment for each job. Doing regular safety checks will help ensure a safe and productive workplace.

Final Words

As you can see, there’s a lot to think about when it comes to running a safe workshop. Investing in the right safety measures will go a long way toward helping you keep your workshop and its workers safe.

If you follow the steps listed above, your workshop should be ready for any potential risks that may come up.

Featured image credit: Wikimedia